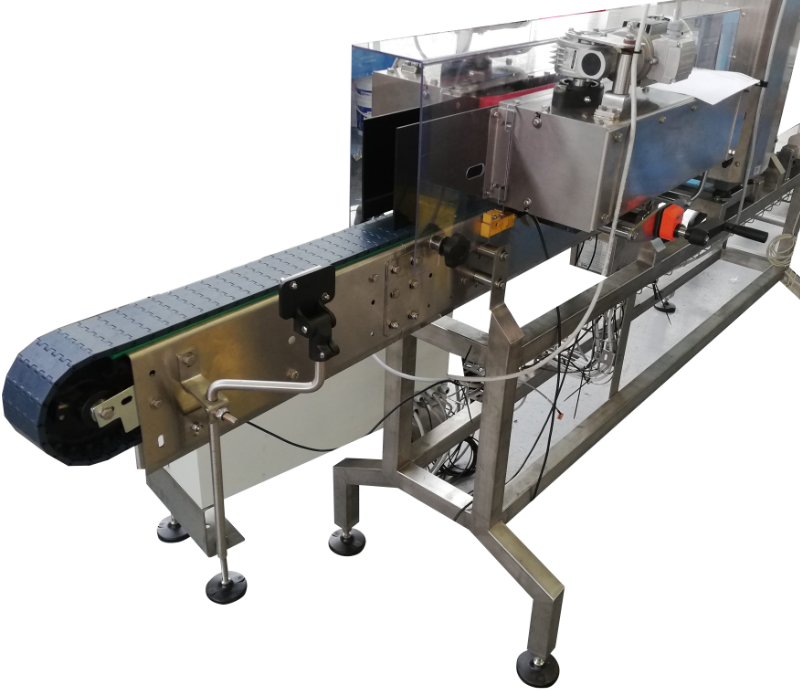

Thevariable interaxis is the handling solution with manual or motorized adjustment, which allows changing the interaxis between two belts to allow maximum flexibility to the production line. This solution accentuates the flexibility of the production line, being able to increase the formats managed within the same line. It is indispensable in detecting fallen products, in the timing at the metal detector inlet or in the passage on central shuttle belts. Moreover, thanks to the application of trapezoidal screws, it is possible to obtain fine and extremely stable adjustments.